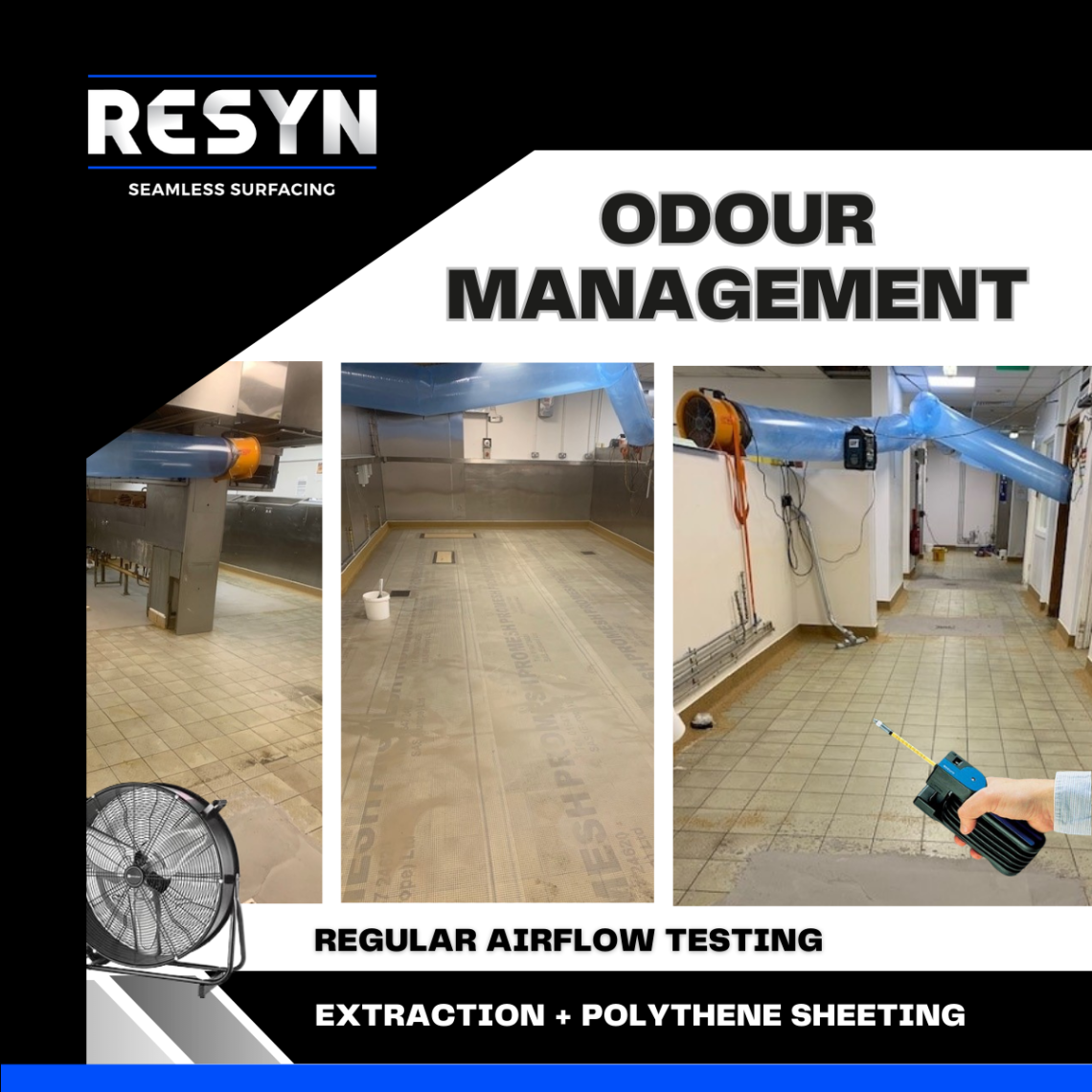

MMA resin floors and odour management

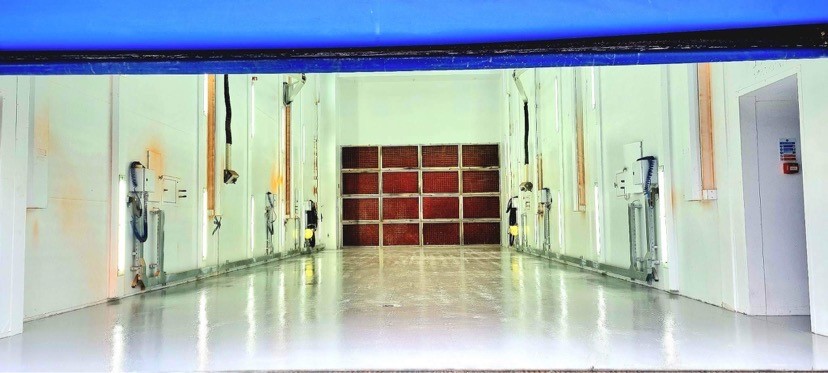

MMA (Methyl Methacrylate) resin floors are well known for their rapid installation and fast curing ability, allowing projects to be completed within very short timescales. The systems are FULLY cured within just two hours of completion, meaning businesses can resume normal operations shortly after installation. MMA resin floors are extremely popular for companies where shutdown […]